Engineering

DAC is an aluminum tube engineer, manufacturer as well as a designer of the tent and outdoor furniture.

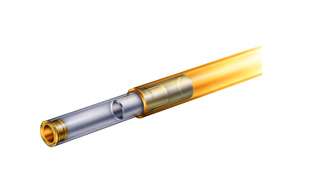

DAC’s engineering team collaborated with the ALCOA Technical Center to develop its proprietary alloy TH72M. This alloy allows DAC to produce poles that are lighter yet strong enough to meet the demands of the most technical tent brands and their customers. DAC is the only company to produce a tube with the minimal thickness of 0.4mm.

DAC is not only an aluminum tube engineer and producer, we are also the designer of out-standing tents and outdoor furniture. The DNA of our development comes from a spirit of not being afraid to fail. We ask how can we build something and then how can we test it? Successful development projects include:

Development of high strength aluminum tube manufacturing processes

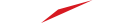

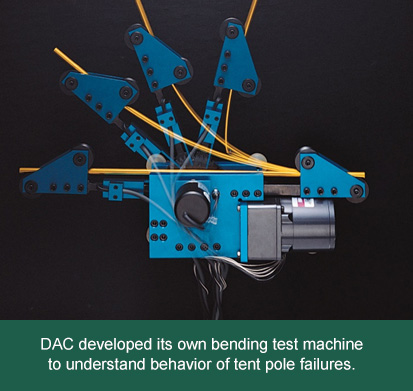

Development of unique machinery to help meet these processes

Development of specific aluminum alloys

Development of new poles to meet customer demands

Development of unique tent architectures

Development of trekking poles

Development of lightweight furniture

Development and implementation of “green” anodizing

Extensive engineering experience and expertise enables DAC to build its’ own machines to advance the production process of all products.

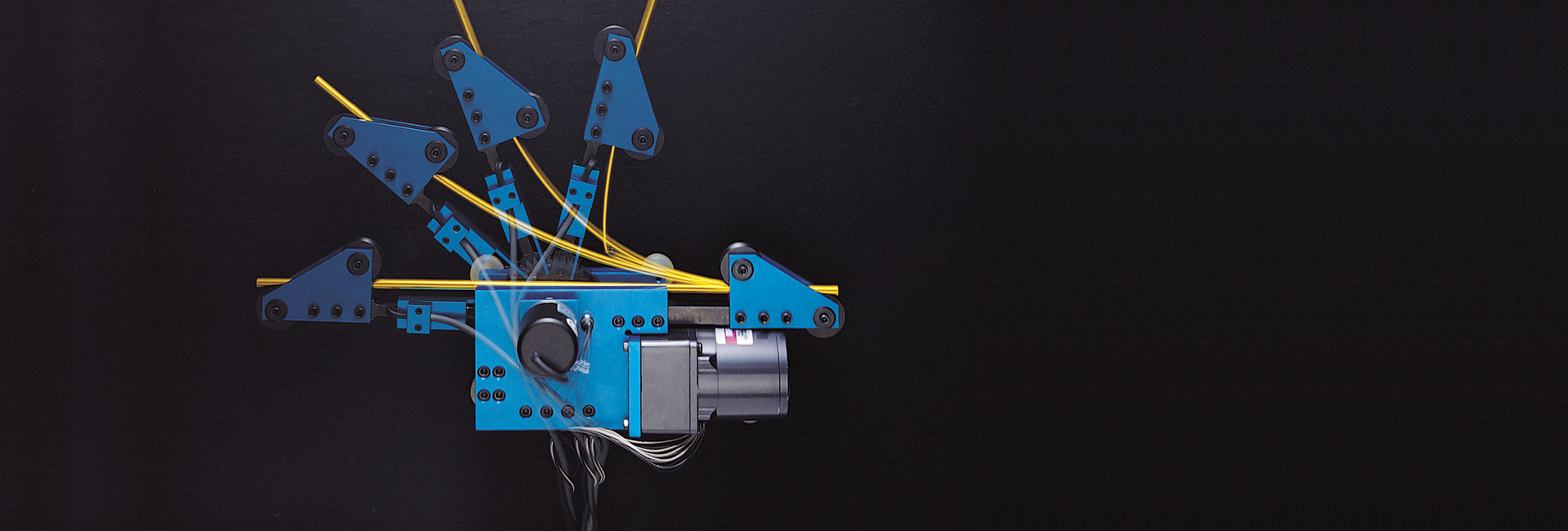

Helinox’s name survived that Jake came up for automatic telescopemount.

Helinox became a brand name for lightweigh outdoor equipment.

Extensive engineering experience and expertise enables DAC to build its’ own machines to advance the production process of all products.

DAC developed its own bending test machine to understand the behavior of tent pole failures.

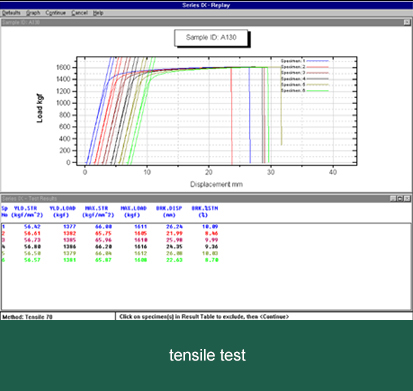

Finite Element Analysis (FEA) of pole breakage was used to develop new and better performing poles.

Organically, aluminum is a soft material.

However, when copper, zinc and magnesium are added to the base aluminum and heat treated, high strength aluminum is created.

DAC worked with the ALCOA Technical Center in Pittsburgh for over four years to develop the proprietary alloy TH72M.

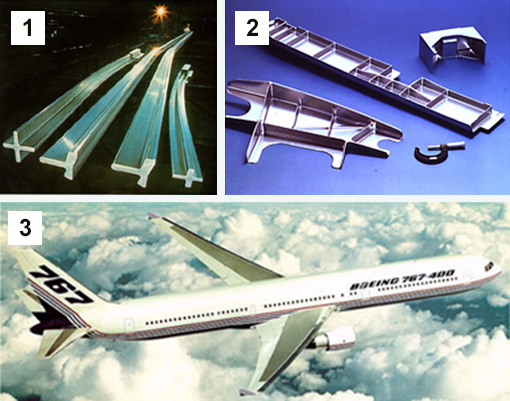

High-Strength 7xxx Alloy

- 1. Alloy 7150/7055 Extrusions

- 2. Alloy 7175/7050 Forgings

- 3. Alloy 7150 Aircraft(upper wings)

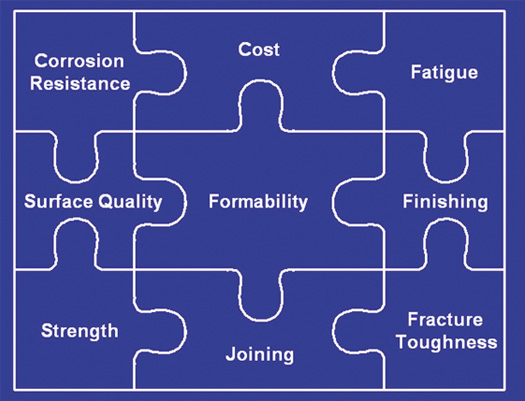

The Alloy Development “Puzzle”

- All aluminum products must function in a variety of ways to meet the customer’s needs.

- Some attributes may trade off against each other (e.g, strength vs toughness)

(*Source : Alcoa Technical Center)

Development of DA17 Poles

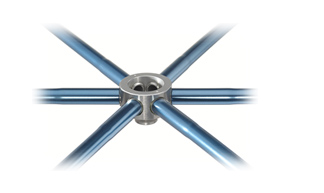

Uni Connector

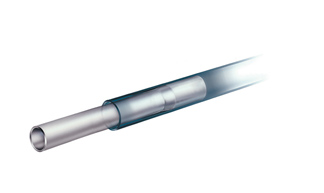

The First Combination Pole

Pressfit Poles Introduced

Introduced the Original Featherlite

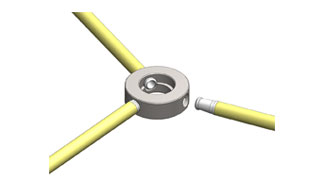

Sunflower

Featherlite SL was introduced

The first of many DAC “Toys” were Introduced

Featherlite NSL Poles were introduced

Green Anodizing came into use on DAC Poles

Introduced DAC engineered 'Whole New Trekking Poles'

J.cot